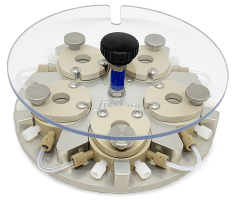

fReactor Classic Complete Kit

Designed by chemists and engineers from the Institute of Process Research and Development at the University of Leeds, the fReactor Classic is simple to assemble and modify, making it suitable for a wide range of continuous-flow processes.

The reactor classic includes 5 continuous stirred tank reactors (CSTR) of 1.8 mL volume each. Heating and mixing are provided by a standard magnetic hotplate stirrer, and fluidic pumps (e.g., HPLC, syringe, peristaltic, gear) are used to drive the reagents around the modules.

Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor Classic delivers a general “plug-and-play” setup suited to multiphasic reactions, allowing chemists to explore continuous-flow processing with little expertise required.

fReactor Classic HASTELLOY Kit

Designed by chemists and engineers from within the Institute of Process Research and Development at the University of Leeds, the fReactor Classic HASTELLOY is simple to assemble and modify, making it suitable for a wide range of continuous-flow processes.

The fReactor Classic HASTELLOY Complete Kit includes 5 x Continuous Stirred Tank Reactors (CSTR) of 1.8 mL volume each, with hastelloy bases featuring toughened glass windows.

Heating and mixing are provided by a standard magnetic hotplate stirrer, and fluidic pumps (e.g., HPLC, syringe, peristaltic, gear) are used to drive the reagents around the modules.

Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor Classic HASTELLOY delivers a general “plug-and-play” setup that is well-suited to multiphasic reactions, allowing chemists to explore continuous-flow processing with little expertise required.

fReactor MAXI Complete Kit

Designed by chemists and engineers from within the Institute of Process Research and Development at the University of Leeds, the fReactor MAXI is simple to assemble and modify, making it suitable for a wide range of continuous-flow processes.

fReactor MAXI includes 5 x Continuous Stirred Tank Reactors (CSTR) of 7.5 mL volume each.

Heating and mixing are provided by a standard magnetic hotplate stirrer, and fluidic pumps (e.g., HPLC, syringe, peristaltic, gear) are used to drive the reagents around the modules.

Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor range delivers a general “plug-and-play” setup that is well-suited to multiphasic reactions, allowing chemists to explore continuous-flow processing, with little expertise required.

fReactor MAXI HASTELLOY Kit

Designed by chemists and engineers from within the Institute of Process Research and Development at the University of Leeds, the fReactor MAXI is simple to assemble and modify, making it suitable for a wide range of continuous-flow processes.

The reactor MAXI HASTELLOY kit includes 5 continuous stirred tank reactors (CSTR) of 7.5 mL volume each, manufactured from Hastelloy.

Heating and mixing are provided by a standard magnetic hotplate stirrer, and fluidic pumps (e.g., HPLC, syringe, peristaltic, gear) are used to drive the reagents around the modules.

Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor range delivers a general “plug-and-play” setup that is well-suited to multiphasic reactions, allowing chemists to explore continuous-flow processing, with little expertise required.

fReactor Photo Flow photochemistry reactor for Flow Chemistry

New Photochemistry in Flow tool The fReactor Photo Flow module was developed by the University of Leeds in conjunction with Asynt and gives scientists the potential to develop and expand their Flow Chemistry work quickly and easily to include photochemistry. This new addition to the Asynt fReactor Flow Chemistry platform is manufactured in the UK and is currently available in two wavelengths to suit your requirements:

• 450 nm (Blue) 10w LED COB chips

•365 nm (UV) 10w LED COB chips

Each fReactor Photo Flow module is available to purchase individually, with easy-to-use plug-and-glow technology positioned over the desired fReactor position in your set-up. With a fully customisable configuration possible, you can choose to use just one of these compact Photo modules on one of the 5 fReactor CSTRs, or add further Photo modules for up to five positions running simultaneously. You can run all five of these from just one power supply using optional splitter leads.

The fReactor platform was developed by the University of Leeds and Asynt Ltd to offer an affordable entry point into the world of flow chemistry. fReactor provides an expanding platform of intuitive and flexible flow reactors for the development of materials and synthesis routes. Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor delivers a general “plug-and-play” setup that is well-suited to multiphasic reactions, allowing chemists to explore continuous-flow processing with little expertise required.